Drilling and Evaluation

Reach your drilling targets and reduce reservoir uncertainty

We set the stage for a lifetime of production. From HPHT deepwater wells to narrow pore-pressure unconventional wells, we offer the careful planning, expert engineering, and exclusive drilling technologies that help you to safely maximize reservoir exposure. Our experienced technicians and industry-leading technologies help you collect, interpret, and apply formation evaluation data to locate the optimal formation target. We leverage our comprehensive wellsite services and innovative cementing and liner systems to build life-of-well integrity that sustains years of healthy production and transforms downhole uncertainty into informed well-construction and production decisions.

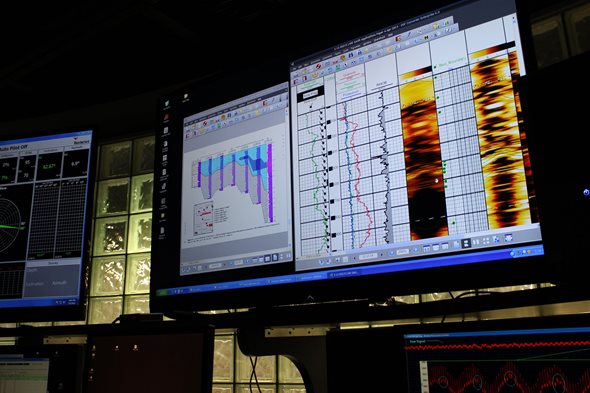

Using a suite of technologies that include rotary-steerable systems, logging-while-drilling services, and borehole-enlargement technologies, we combine real-time formation analysis with innovative drilling tools to maximize drilling efficiency in any environment.

Fluids and drilling-waste management form an interdependent relationship that impacts well-construction efficiency. Our integrated approach leverages a deep selection of fluid systems that range from conventional to custom-designed drilling, drill-in, and completion fluids. We then match the optimal fluid regime to our advanced waste-management systems to minimize net waste and overall fluid costs.

Our pressure-management technologies—including rotating control devices and blowout preventers—provide you with fundamental well control, and our critical control services mobilize experienced technicians to respond to well emergencies.

Working in standard to extreme drilling environments, our technologies deliver real-time petrophysical, geosteering, imaging, geomechanical, and geophysical data that enhance reservoir understanding and enable on-the-fly drilling adjustments.

We provide actionable wireline data and flawless service execution from early field exploration to mature-field production. Our proprietary technologies assess productivity, diagnose downhole issues, and inform infill drilling programs.

Gain insight into your reservoir with intuitive answer products

Interpretation and Evaluation ServicesOur extensive portfolio of answer products includes high-resolution borehole image interpretation, acoustic slowness and geomechanical applications, petrophysical analysis, and well-integrity issue identification.