Objectives

- Reduce costs associated with total downhole losses and stuck pipe incidents. Ten of the sixteen wells involved in this campaign suffered from total losses.

- Maintain a full column of fluid in the annulus.

- Improve safety and rate of penetration (ROP).

Our Approach

- In collaboration with the customer, Weatherford decided that pressurized mud cap drilling (PMCD), a type of managed pressure drilling (MPD), was the optimal drilling technique for this well. PMCD involves sealing the mud-return line and then intermittently pumping a column of mud down the back side of the drillstring. The mud serves as a barrier, or cap, for annular pressure control. Processed water acts as a sacrificial drilling fluid to minimize losses of costly drilling mud.

- Weatherford provided qualified, experienced personnel on location to execute the PMCD operation and supplied all required MPD equipment, including a SafeShield® Model 7100 rotating control device (RCD), valves, piping, and drillstring float valves.

- Several wells required additional safety measures due to drilling in gas cap formations. The use of RCDs sealed the wells and prevented the release of harmful gases to the surface.

- The PMCD approach in this field involved detecting total losses and ensuring no surface leaks. To accomplish this, field personnel lined up and activated the mud cap, monitored well behavior, installed the bearing, and pumped the 65 pcf LAM in the back side until the pressure was observed on the RCD. This was an indicator that a full column of fluid was achieved.

- The Weatherford team maintained RCD pressure and conducted all operations with a focus on safety, communication, and proper equipment handling.

Value to Customer

- The Weatherford PMCD campaign included significant cost savings, improved drilling efficiency, enhanced safety, and effective management of total losses, leading to optimized well performance and reduced nonproductive time.

- This deployment enhanced the drilling safety of these types of wells and ensured well integrity by allowing immediate action based on RCD pressure observations, preventing gases from reaching the surface.

- PMCD played a key role in managing losses, as the rig's mixing capacity is limited to low volumes.

- The campaign successfully saved 83,700 bbl of mud, with densities ranging from 74 to 95 pcf.

Learn More

Details

Location

Middle East

Well Type

Workover

Formation

Arabs

Hole Size and Angle

6-1/8 in., 66°

Casing Size and Type

9-5/8 in., 40#

Liner Size and Type

7 in., 32#

Depth

6,400-7,000 ft (1,950-2,133 m) to 11,000-12,000 ft (3,352-3,657 m)

Products/Services

×

![]()

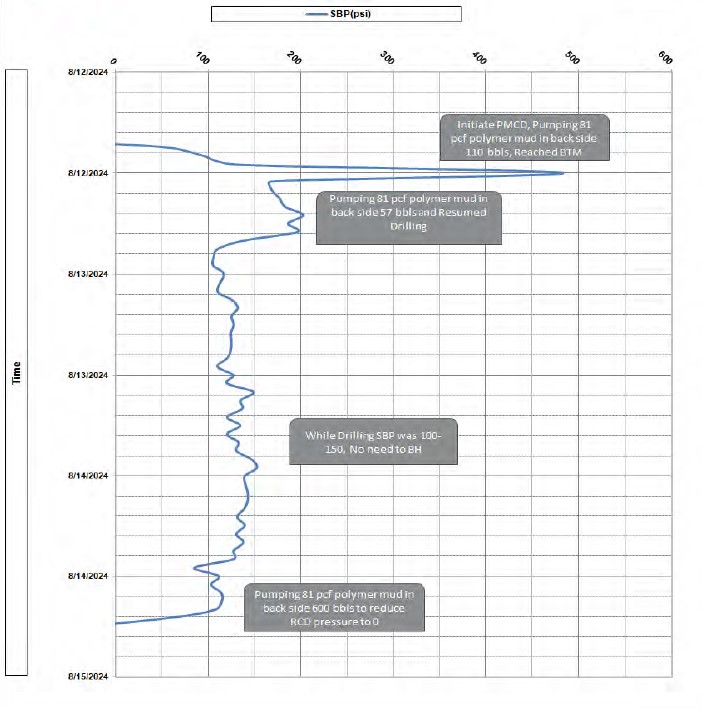

The RCD pressure trend in 8 1/2-in. hole section.

×

![]()