Drilling Services

Maximize reservoir exposure and reach your preferred target

We help you to safely drill from one casing point to the next in the shortest possible time. Using a suite of technologies that include rotary-steerable systems, logging-while-drilling services, surface logging systems, and borehole-enlargement technologies, we combine real-time formation analysis with innovative drilling tools to maximize drilling efficiency in any environment.

With three positions, multiple applications, and dynamic activation options, the JetStream RFID circulation sub enables remote, selective, unlimited actuation for efficient borehole cleaning and LCM spotting.

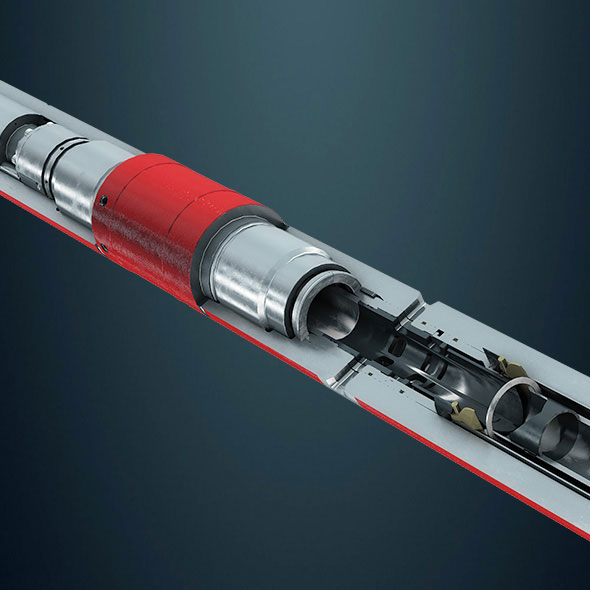

Our measurement-while-drilling (MWD) systems leverage several proprietary telemetry methods to reliably transmit data to surface, even in wells subject to heavy vibration, high-lost-circulation-material content, high flow rates, and high doglegs.