Automated Connection Integrity

Building wells that

last a lifetime

The future of well construction is here. Vero automated connection integrity goes above and beyond tubular running for unquestionable success.

Rather than rely on human judgment for connection evaluation, we apply artificial intelligence to eliminate errors or oversights that can lead to safety incidents and costly remediation.

VERO GOES BEYOND TUBULAR RUNNING FOR ZERO CONNECTION ISSUES

Eliminate catastrophic well failures and mitigate safety risks

Reduce total well construction costs

Protect your corporate reputation and profitability

Transforming rig floor operations through integration and automation

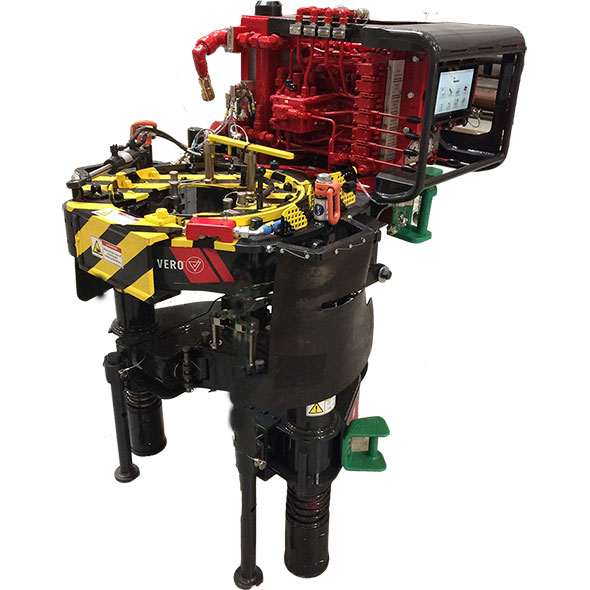

VERO OneTouch Automated Tubular SystemThe VERO OneTouch system streamlines all drilling, casing, and completions operations into a single, hands-free system, delivering revolutionary rig floor safety and efficiency with fewer personnel requirements and greater marketability.