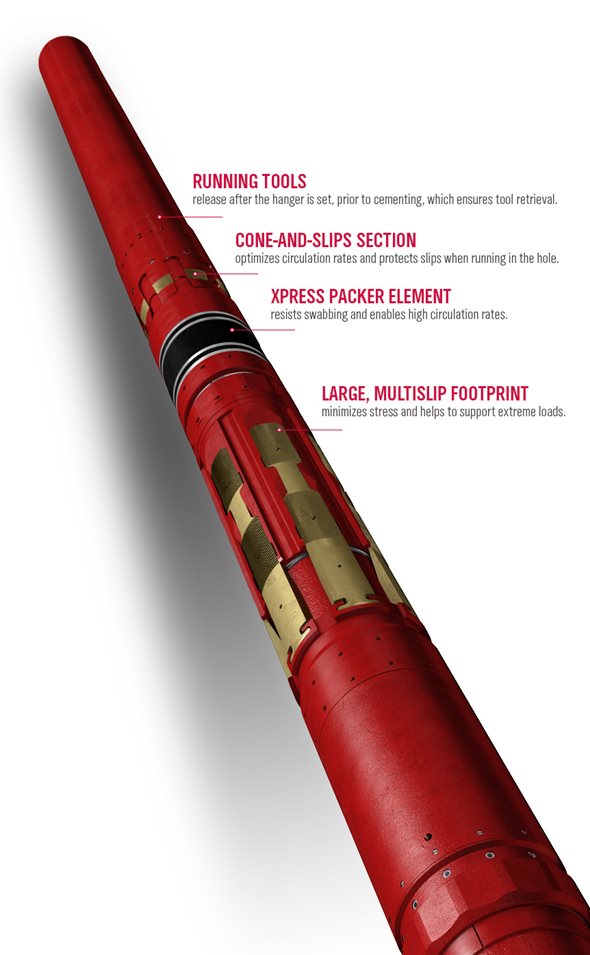

Boost operational efficiency with a streamlined design

The Xpress System Advantage

This system accommodates common casing sizes, and its interchangeable packing elements can be adapted for any application. Major liner-system components are run together as a single integrated package.

ADVANCED DESIGN - IMPROVED PERFORMANCE

Synergy – Flexibility – Reliability

Our advanced features improve hanger and packer performance, no matter where you operate.

- Liner hanger and packer consolidated onto a single mandrel, thus eliminating two connections and their potential leak points, as well as increasing torque capability throughout the liner system.

- Three-piece packing elements create a reliable seal that isolates gas migration.

- Nitrided slips ensure that the liner hanger can be set in the hardest grades of host casing, and its large slip-contact area minimizes stress in the host casing, to boost reliability.

Increase Operational Flexibility

A range of options

Our Xpress liner system components stand up to your toughest wells. The PBR optimizes burst, collapse, and sealing integrity without sacrificing flow-by area. A cementing packoff in the hanger-packer body delivers a positive seal during cementing operations. The result is greater reliability when running in the hole or circulating at high flow rates.

The unibody design opens up a range of options:

- Ream the liner to bottom

- Rotate during cementing

- Hydraulically set the hanger, and mechanically set the packer

- Run in low angle or high-angle wells

- Run in long laterals

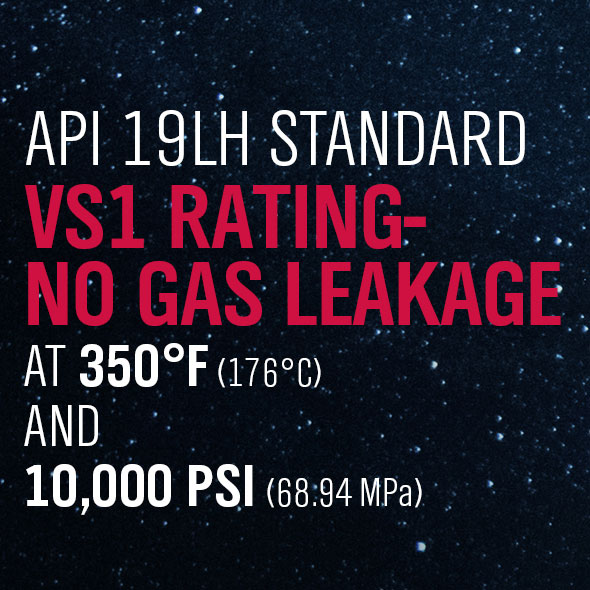

Greater Reliability

Tested to the Highest Standards

This robust system meets or exceeds the new API 19LH standard for liner hangers. It achieved the highest API qualification for liner hangers, earning a VS1 rating with absolutely no leakage during rigorous gas testing at temperatures up to 350°F (176°C) and pressures up to 10,000 psi (68.94 MPa).

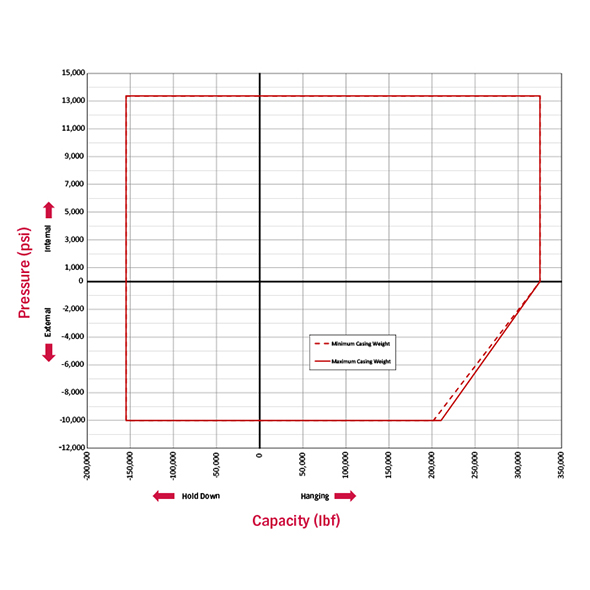

API 19LH Performance Envelope

The Xpress liner hanger system is engineered for performance.

Liner system teams install excellence

Weatherford People

Our liner systems crews have the technology and the know-how to deliver outstanding service and installations.

Iraq

LINER SYSTEMS DELIVER INCREASED EFFICIENCY AND TIME SAVINGS

2 WELLS

7-in., 29-LB/FT LINER STRING

3 HOURS RIG TIME SAVING

United Arab Emirates

LINER SYSTEMS DELIVER FLAWLESS INSTALLATION

2 WELLS

7-in., 29-LB/FT LINER STRING

0 NPT