Endura® Dual-String Section Mill

Plug and abandon

in half the time

Mill adjacent strings and achieve verifiable well integrity.

The Endura® dual-string section mill creates your preferred abandonment environment—a stable, permanent, and verifiable rock-to-rock barrier—and halves the P&A rig time average. The barrier seals across the borehole by milling both inner and outer strings and mimics natural bedding.

Set a rock-to-rock barrier and know that it’s done right

Expose more of the rock face, faster

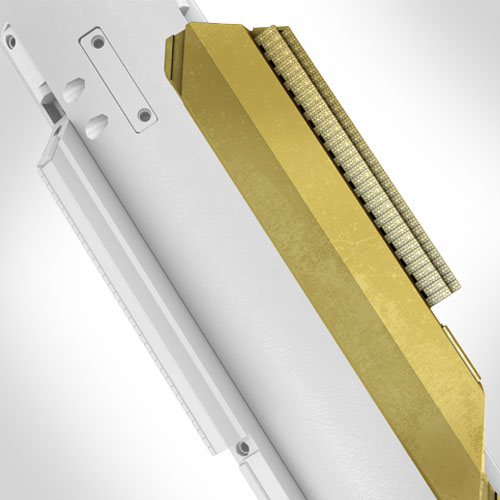

Cutting-edge blades

Based on RipTide® drilling reamer technology, the mill features separate stabilizers and specially designed 4.5- to 13-in.-long carbide cutting structures that enable through-casing milling of the adjacent casing string. The inserts cut radially and axially downward to improve milling and create finer, more manageable cuttings.

Reduce milling time by half

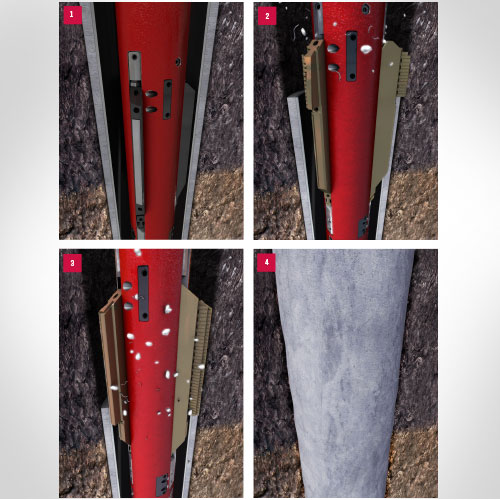

The ideal cement-to-formation bond

To plug and abandon a typical offshore well, the technology mills through the 9 5/8-in. casing like any other section mill. The difference lies in trips dedicated to the outer string. The Endura dual-string section mill passes through the restricted ID of the 9 5/8-in. casing string to the open section.

Hydraulic stabilizers expand inside the 13 3/8-in. outer casing to centralize the tool. The full-gauge cut-out blades remove approximately 15 ft of casing to prepare for milling. Using advanced cutting technologies that improve swarf-handling and reduce birdnesting, the mills engage and then mill through the remaining section of outer casing.

Our client saved 5 days of rig time and reduced overall risk

Field-proven results

One operator faced top-up cement in the annulus between the 9 5/8- and 13 3/8-in. casing strings in an offshore gas well and could not cut and pull casing as planned. Weatherford deployed the Endura dual-string section mill and safely exposed a 98-ft section of formation. The operation not only provided a verifiable rock-to-rock barrier, but also saved the customer 5 days of rig time.