Latest Products

Latest Products

-

New Product

Remote-Opening Barrier Valve

-

New Product

ForeSite® Power Regenerative System

-

New Product

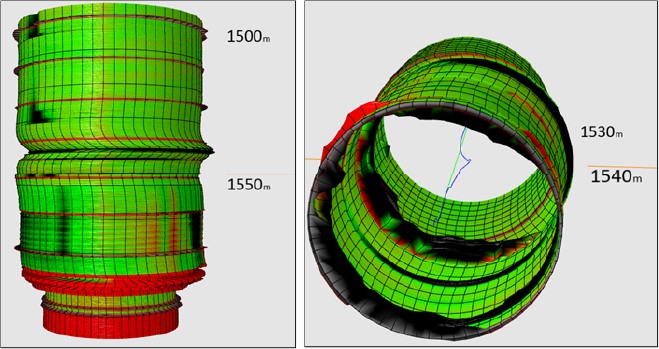

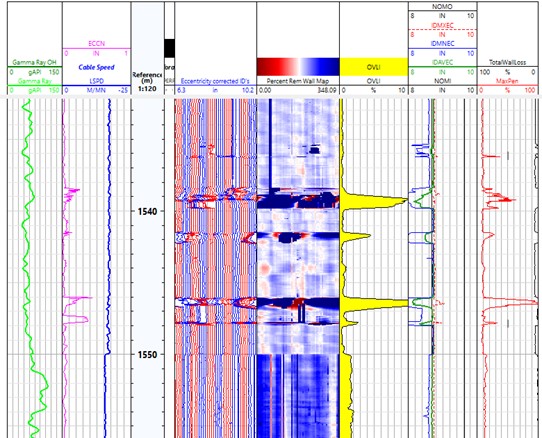

Tubular Running Assurance

-

New Product

MARS™

-

New Product

MODUS™

- See all Products

Latest News

Latest News